Fage

An fitar da sabon sigar UL 1642. Ana ƙara madadin gwajin tasiri mai nauyi don ƙwayoyin jaka. Takamaiman buƙatun sune: Don jakar jakar da ke da ƙarfin da ya fi 300 mAh, idan ba a wuce gwajin tasiri mai nauyi ba, ana iya fuskantar gwajin extrusion na Sashe na 14A.

Kwayoyin jaka ba su da wani akwati mai wuya, wanda sau da yawa yakan haifar da fashewar tantanin halitta, fashewar famfo, tarkace da ke tashi da sauran mummunar lalacewa ta hanyar rashin nasara a gwajin tasiri mai nauyi, kuma yana sa ba zai yiwu ba a gano guntun ciki na ciki wanda lalacewa ta hanyar ƙira ko lahani. . Tare da gwajin murkushe sandar zagaye, za a iya gano lahani a cikin tantanin halitta ba tare da lalata tsarin tantanin halitta ba. An yi bita tare da la'akari da wannan yanayin.

Gwajin kwarara

- Ana cajin samfurin cikakke kamar yadda mai ƙira ya ba da shawarar

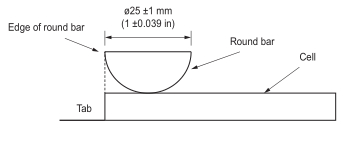

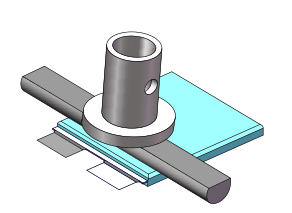

- Sanya samfurin a kan shimfidar wuri. Saka sandar karfe zagaye da diamita na 25±1mm a saman samfurin. Gefen sandan ya kamata a daidaita shi tare da saman gefen tantanin halitta, tare da axis na tsaye daidai da shafin (FIG. 1). Tsawon sanda ya kamata ya zama aƙalla 5mm fadi fiye da kowane gefen samfurin gwaji. Don sel masu shafuka masu inganci da mara kyau a ɓangarorin daban-daban, kowane gefen shafin yana buƙatar gwadawa. Ya kamata a gwada kowane gefen shafin akan samfurori daban-daban.

- Auna kauri (haƙuri±0.1mm) don sel dole ne a yi su kafin gwaji daidai da Shafi A na IEC 61960-3 (Kayan na biyu da batura waɗanda ke ɗauke da alkaline ko wasu electrolytes marasa acidic - Kwayoyin lithium na biyu masu ɗaukar nauyi da batura - Sashe na 3: Prismatic da cylindrical lithium secondary. sel da batura)

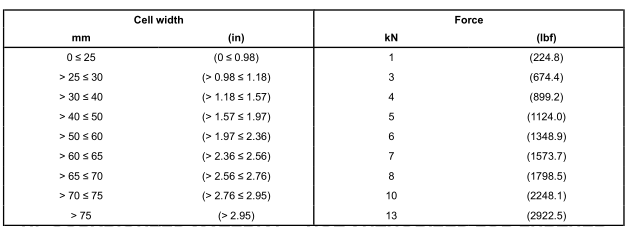

- Sa'an nan kuma ana amfani da matsi a kan sandar zagaye kuma ana rikodin motsi a tsaye (FIG. 2). Gudun motsi na farantin latsa ba zai wuce 0.1mm/s ba. Lokacin da nakasar tantanin halitta ya kai 13±1% na kauri daga cikin tantanin halitta, ko matsa lamba ya kai ga ƙarfin da aka nuna a cikin Tebur 1 (kaurin sel daban-daban daidai da ƙimar ƙarfi daban-daban), dakatar da motsin farantin kuma riƙe shi har tsawon 30s. Gwajin ya ƙare.

- Babu wuta ko fashewar samfurori.

Binciken gwaji

- Zaɓin matsayi na extrusion: yankin shafin sanda gabaɗaya shine yanki mai rauni na tantanin halitta, kuma matsayin shafin yana ɗaukar mafi girman damuwa lokacin da ake matse shi. Dalilan su ne:

a) Rarraba kauri mara daidaituwa (daidaitaccen kauri tsakanin sandar sandar da abin da ke kewaye da shi yana haifar da rarraba damuwa mara daidaituwa)

b) Alamar walda a cikin yankin shafin (rarraba damuwa a wurin walda da kuma mara walƙiya)

- Zaɓin sandar zagaye: Diamita na sandar zagaye shine 25mm. An zaɓi wannan ƙimar don rufe duk yankin shafin sandar sandar a cikin tantanin halitta (musamman yankin da ke rufe haɗin gwiwar sandar sandar sandar sandar).

- 13±1% nakasawa: A halin yanzu, mafi girman kauri a kasuwa shine 2mm. Saboda tasirin shingen baturi ko tsarin marufi, ana buƙatar aƙalla nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in 8% don matsawa zuwa haɗin gwiwar sandar sandar sandar sandar, amma zai haifar da fashewar lantarki kai tsaye idan nau'in canjin ya yi girma da yawa. Darajar 13±An zaɓi 1% a cikin wannan bita, yana nufin matsakaicin matsakaici 15% a cikin gwajin extrusion a cikin IEC 62660-3.

- Zaɓin samfur: Ya kamata a lura cewa wannan gwajin don ƙwayoyin jaka ne kawai waɗanda ƙarfinsu ya fi 300mAh kuma waɗanda abubuwa masu nauyi ba su taɓa su ba. Ana buƙatar samfurori 5. Kwayoyin Silindrical ko prismatic da sel jakunkuna da abubuwa masu nauyi suka buge su't wajibi ne a yi la'akari da wannan gwajin.

Takaitawa

Sabuwar gwajin extrusion na sandar zagaye ya bambanta da ainihin gwajin extrusion na UL 1642. Gwajin extrusion na asali shine amfani da lebur extrusion, da amfani da ƙarfin 13kN akai-akai ba tare da riƙe lokaci ba. Ya dace da kowane nau'in tantanin halitta. Wannan gwajin yana nazarin ƙarfin injina na tantanin halitta gaba ɗaya (ciki har da shari'ar) da kuma ikon da zai iya jure damuwa na inji; yayin da extrusion igiyar zagaye kawai gwada wani ɓangare na tantanin halitta, ƙaramin yanki na mai shiga zai sa damuwa na ciki ya mayar da hankali, mai sauƙi don kaiwa ga gajeren kewaye na ciki. Musamman ma, an zaɓi matsayi na extrusion a cikin yanki mai rauni na sandar igiya tab waldi, wanda zai iya bincikar lafiyar lafiyar tantanin halitta.

A halin yanzu, ana amfani da wannan hanyar zagaye na sanda a cikin gwajin extrusion na jakar jaka a cikin GB 31241. MCM yana da ƙwarewar gwaji mai yawa a cikin wannan aiki.

Lokacin aikawa: Nuwamba-16-2022