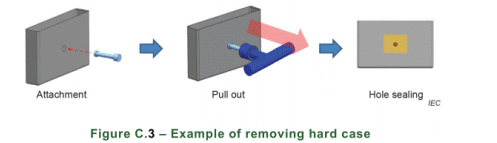

Menene'sabo a cikin sabuwar IEC62660-3

IEC 62660-3: 2022 ya bambanta daga sigar 2014 kamar haka. Rukunin Dalilan Canji an ƙididdige shi ne daga ainihin aikinmu, wanda zai iya zama darajar a matsayin tunani.

Cikakkun Nazari akan Sabon Binciken Cikin Gida

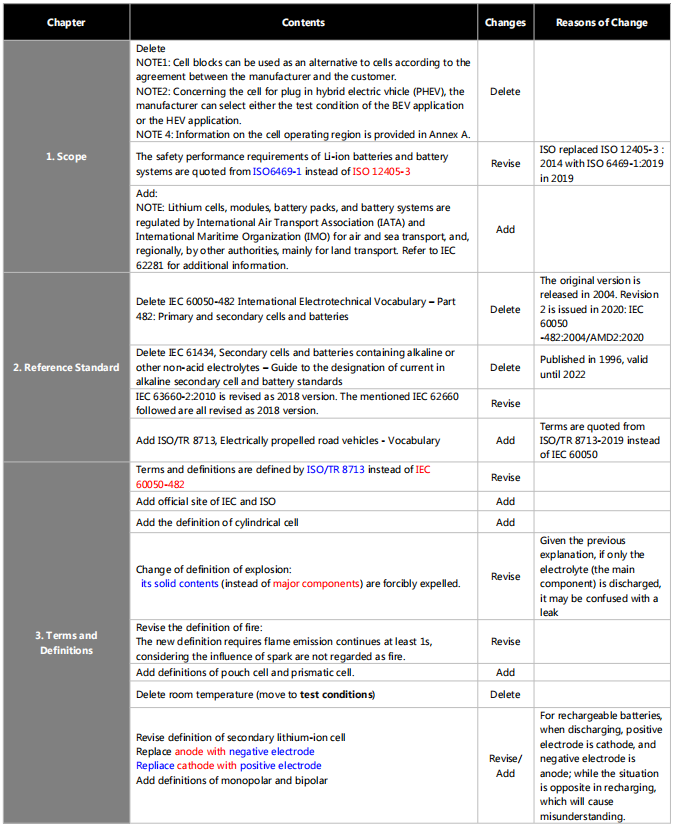

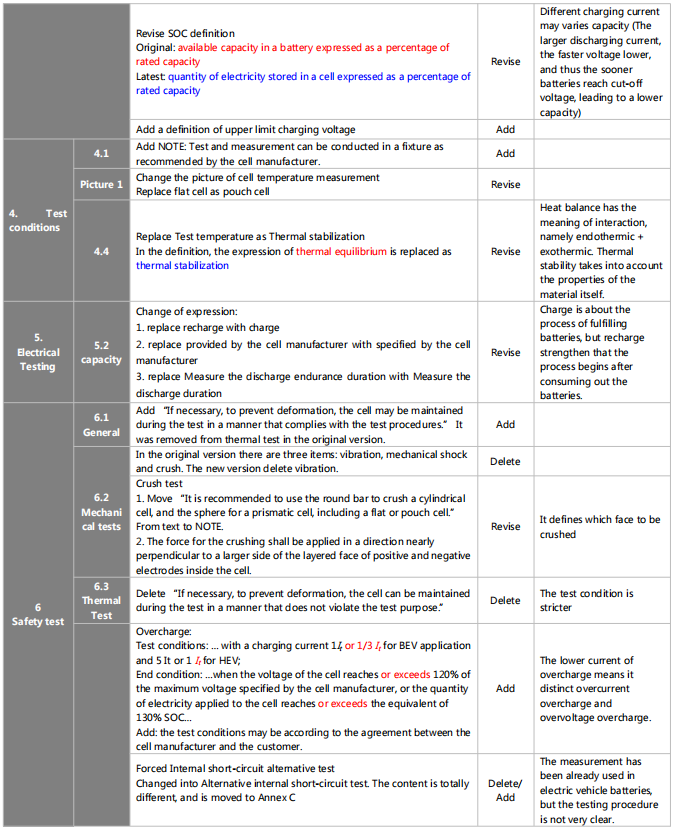

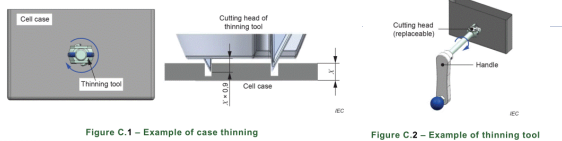

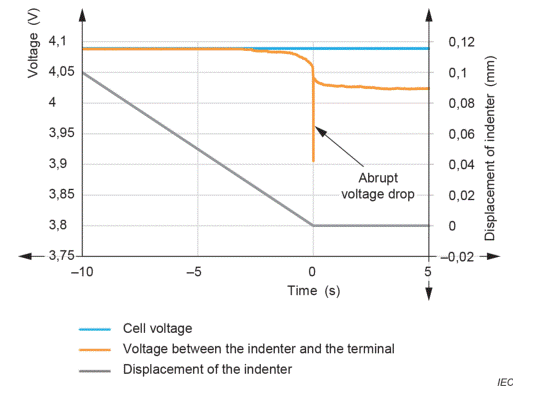

Sabuwar sigar ta ambaci sabon gwajin gajeriyar gajeriyar ciki. Sabuwar hanyar ita ce ta motsa gajeriyar ciki ta hanyar shiga don ƙirƙirar shafuka masu kyau da mara kyau a cikin gajeriyar Layer 1 da 2. Hanyar ita ce kamar haka:

1. Shirya tantanin halitta: Hana rami a tsakiyar mafi girman fuska (kamar yadda aka kwatanta a ƙasa) ko ajiye rami lokacin da ake kera don iska.

2. Gyaran tantanin halitta: Bayan cikar caji, gyara tantanin halitta a cikin kayan aikin gwaji. Tantanin halitta za a keɓe ta hanyar lantarki daga benci na gwaji. Tantanin halitta da mai shiga za su motsa tare da madaidaicin axis. Matsayin shigarwa zai kasance iri ɗaya kamar yadda aka bayyana a cikin tilas a takaice.

3. Haɗa layin saka idanu: Layin kula da zafin jiki akan farfajiyar tantanin halitta, ƙarfin wutar lantarki na tantanin halitta, ƙarfin wutar lantarki na ƙarshen tantanin halitta da mai ƙima (za a yi rikodin ƙarfin lantarki tare da ƙimar samfurin aƙalla 1000Hz);

4. Danna mai niyya zuwa tantanin halitta tare da saurin gudu na 0.01mm/s. Gudun latsawa na iya zama da sauri fiye da 0.01mm/s idan ana iya samun gajeriyar da'ira mai Layer Layer ɗaya ko biyu. Ya kamata a dakatar da latsa lokacin da aka gano faɗuwar wutar lantarki ba zato ba tsammani, sannan a saki mai nema daga tantanin halitta kuma a saki latsa.

5. Kula: Bayan dannawa, za a kiyaye tantanin halitta na 1h. Mai nema zai kasance a wurin a wurin tsayawa, kuma a kiyaye shi a cikin ± 0.02mm a cikin kwatancen X, Y da Z har zuwa ƙarshen gwaji, gami da lokacin kallo.

6. NOTE: Bayan karshen lura, da cell za a iya disassembled don duba yawan shorted yadudduka.

Sanarwa ta MCM:

1. A cikin sabon ma'aunin ISO 6469 IS da aka nakalto maimakon ISO 12405-3. Dalili kuwa shine ISO a hukumance ta maye gurbin ISO 12405-3 da ISO 6469. A halin yanzu ISO 12405-4 ta maye gurbin ISO 12405-1 & ISO 12405-2. Masana'antun na iya yin la'akari da wannan yanayin yayin amfani da ISO 12405-1/-2/-3

2. Akwai wahalhalu guda biyu a cikin sabon tilastawa gajeriyar ciki. Daya shine shiga cikin ramin idan babu rami da aka tanada lokacin samarwa. Don haka masana'antun na iya yin la'akari da tanadin rami don shirya gwajin. Dayan kuma shine sa ido. Ma'auni yana buƙatar aƙalla 1000Hz na rikodin rikodi. Mafi girman yawan rikodi, mafi ingancin rikodin zai kasance; don haka muna ba da shawarar yin amfani da rikodin sauri. Duk da haka yawancin na'urori masu shiga ba sa goyan bayan rikodi na wutar lantarki aiki tare. Ana buƙatar sabbin na'urori ko sabbin shirye-shiryen sarrafawa.

3. MCM ya riga ya dandana a cikin irin wannan gajeriyar gajeriyar ciki. Za mu iya ba da wannan sabis ɗin gwaji.

Lokacin aikawa: Jul-05-2022