Fage

Yada yanayin zafi na module yana fuskantar matakai masu zuwa: Tarin zafi bayan cin zarafi na tantanin halitta, runaway thermal thermal sannan module thermal runaway. Gudun zafi daga tantanin halitta ɗaya ba shi da tasiri; duk da haka, lokacin da zafi ya yada zuwa wasu sel, yaduwa zai haifar da sakamako na domino, wanda zai haifar da rudani na thermal na dukan tsarin, yana sakin makamashi mai yawa. Hoto 1nunas sakamakon thermal runaway gwajin. Module ɗin yana kan wuta saboda yaɗuwar da ba za a iya jurewa ba.

Ƙunƙarar zafin da ke cikin tantanin halitta zai bambanta bisa ga kwatance daban-daban. Ƙididdigar ƙimar zafin zafi zai kasance mafi girma a cikin shugabancia layi dayatare da mirgina core na tantanin halitta; yayin da jagorar da ke tsaye zuwa jigon nadi yana da ƙananan ƙarfin aiki. Saboda haka thermal baza daga gefe zuwa gefe tsakanin sel yana da sauri fiye da yadda yake yi ta shafuka zuwa sel. Saboda haka ana iya ganin yaduwa a matsayin yaduwa mai girma ɗaya. Kamar yadda aka ƙera na'urorin baturi don haɓakar ƙarfin ƙarfi, sarari tsakanin sel yana ƙara ƙarami, wanda zai ƙara haɓaka haɓakar zafi. Saboda haka, murkushe ko toshe yaduwar zafi a cikin tsarin za a yi la'akari da shi azamantasiriive hanyar rage hatsarori.

Hanyar da za a murkushe guduwar thermal a cikin module

Zamu iya hana guduwar zafi a hankali ko a hankali.

Danniya mai aiki

Matsakaicin yaɗuwar thermal mai aiki ya dogara ne akan tsarin sarrafa zafi, kamar:

1) Sanya bututun sanyaya a ƙasa ko ɓangarorin ciki na ƙirar, kuma cika da ruwa mai sanyaya. Ruwan sanyaya ruwa mai gudana yana iya rage yaɗuwar yadda ya kamata.

2) Saita bututun kashe wuta a saman module. Lokacin da akwai guduwar zafi, yawan zafin da ake fitarwa daga baturi zai sa bututun su fesa abin kashewa don hana yaɗuwa.

Koyaya, kulawar thermal yana buƙatar ƙarin abubuwan haɗin gwiwa, haifar da farashi mai girma da ƙarancin ƙarfin kuzari. Hakanan akwai yuwuwar tsarin gudanarwa bazai yi tasiri ba.

Ƙunƙarar motsi

Ƙunƙwasawa mai wucewa yana aiki ta hanyar toshe yaduwa ta hanyar abu mai adiabatic tsakanin sel masu gudu na zafi da sel na yau da kullun.

A al'ada kayan ya kamata ya kasance cikin:

- Low thermal watsin. Wannan shine don rage saurin yaduwar zafi.

- High zafin jiki juriya. Kayan abu bai kamata ya warware a ƙarƙashin babban zafin jiki ba kuma ya rasa ikon juriya na thermal.

- Ƙananan yawa. Wannan shi ne don rage tasirin ƙarar-makamashi da yawan yawan kuzari.

Kayan da ya dace zai iya toshe zafi yana yadawa tare da ɗaukar zafi.

Bincike akan abu

- Airgel

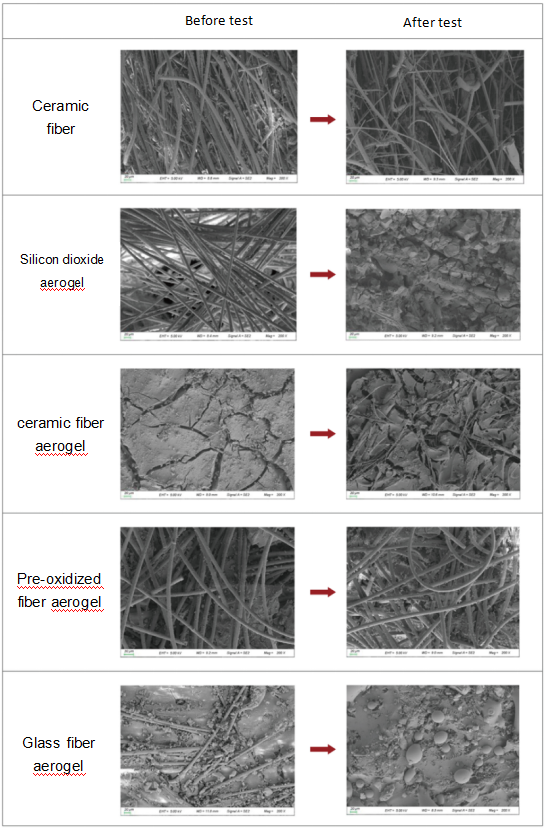

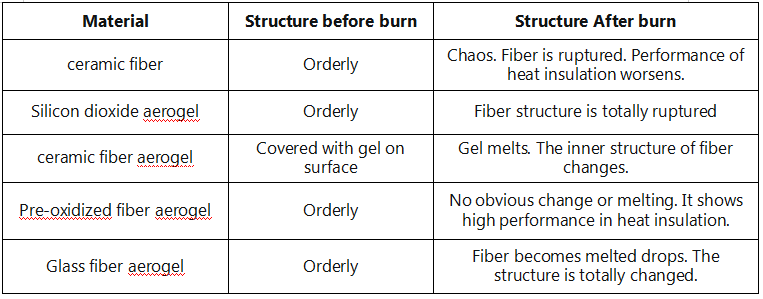

Ana kiran Airgel a matsayin "mafi kyawun kayan rufewar zafi". Ana yin shi da kyau a cikin rufin zafi da auna haske. Ana amfani dashi ko'ina a tsarin baturi don kariyar yaduwar zafi. Akwai nau'ikan aerogel da yawa, kamar silicon dioxide aerogel, aerogel, gilashin fiber airgel da fiber pre-oxidized. Airgel zafi rufi Layer na kayan daban-daban suna da tasiri daban-daban akan guduwar thermal. Wannan shi ne saboda nau'ikan ma'auni na thermal conductivity coefficient, wanda ke da alaƙa sosai da ƙananan tsarin sa. Hoto 2 yana nuna bayyanar SEM na abubuwa daban-daban kafin da kuma bayan ƙonawa.

Bincike ya nuna cewa ko da yake fiber zafin rufi yana da ƙasa a cikin farashi, aikin hana yaduwar zafi ya fi muni fiye da kayan airgel. Daga cikin nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan ma'auni ma'auni suna yin aiki mafi kyau kamar yadda yake kiyaye tsarin bayan ƙonewa. Ceramic fiber airgel kuma yana aiki da kyau a cikin rufin zafi.

- Abun canza lokaci

Hakanan ana amfani da kayan canjin lokaci don murkushe yaɗuwar zafin zafi saboda adana zafinsa. Kakin zuma PCM ne na kowa, tare da tsayayyen yanayin canjin lokaci. A lokacin thermalguduwa, zafi yana fitowa sosai. Saboda haka PCM ya kamata ya sami highyina shafe zafi. Duk da haka, kakin zuma yana da ƙananan ƙarancin zafin jiki, wanda zai yi tasiri ga ɗaukar zafi. Don haɓaka aikin sa, masu bincike suna ƙoƙarin haɗa kakin zuma tare da sauran kayan, kamar ƙara ƙwayar ƙarfe, amfani da kumfa na ƙarfe don ɗaukar PCM, ƙara.graphite, carbon nano tube ko fadada graphite, da dai sauransu Fadada graphite kuma iya kame harshen wuta lalacewa ta hanyar thermal gudu.

Hydrophilic polymer shima nau'in PCM ne don hana titin jirgin sama. Abubuwan polymer hydrophilic na yau da kullun sune: colloidal silicon dioxide, cikakken maganin calcium chloride,Tetraethyl phosphate, tetraphenyl hydrogen phosphate, sodium polyacrylate, da dai sauransu.

- Haɗaɗɗen abu

Ba za a iya hana guduwar thermal ba idan muka dogara da aerogel kawai. Don nasararufezafi, muna bukatar mu hada airgel tare da PCM.

Bayan kayan masarufi, muna kuma iya gina kayan mai-Layi da yawa tare da ƙididdige ƙimar thermal conductivity a wurare daban-daban. Za mu iya amfani da high thermal conductivity abu don gudanar da zafi daga cikin module, da kuma sanya zafi rufi abu tsakanin sel don takura thermal yaduwa.

Kammalawa

Don sarrafa yaɗuwar zafin zafi abu ne mai rikitarwa. Wasu masana'antun sun yi wasu hanyoyin magance zafi da ke yaduwa, amma har yanzu suna neman wani sabon abu, don rage farashin da tasiri akan yawan makamashi. Har yanzu muna mai da hankali kan sabon bincike. Babu"super material” wanda zai iya toshe runaway thermal gaba ɗaya. Yana buƙatar gwaje-gwaje da yawa don samun mafita mafi kyau.

Lokacin aikawa: Maris-10-2023